Advanced Decarb Furnaces – Precision Engineering for High-Performance Steel

Advanced Decarb Furnaces – Precision Engineering for High-Performance Steel

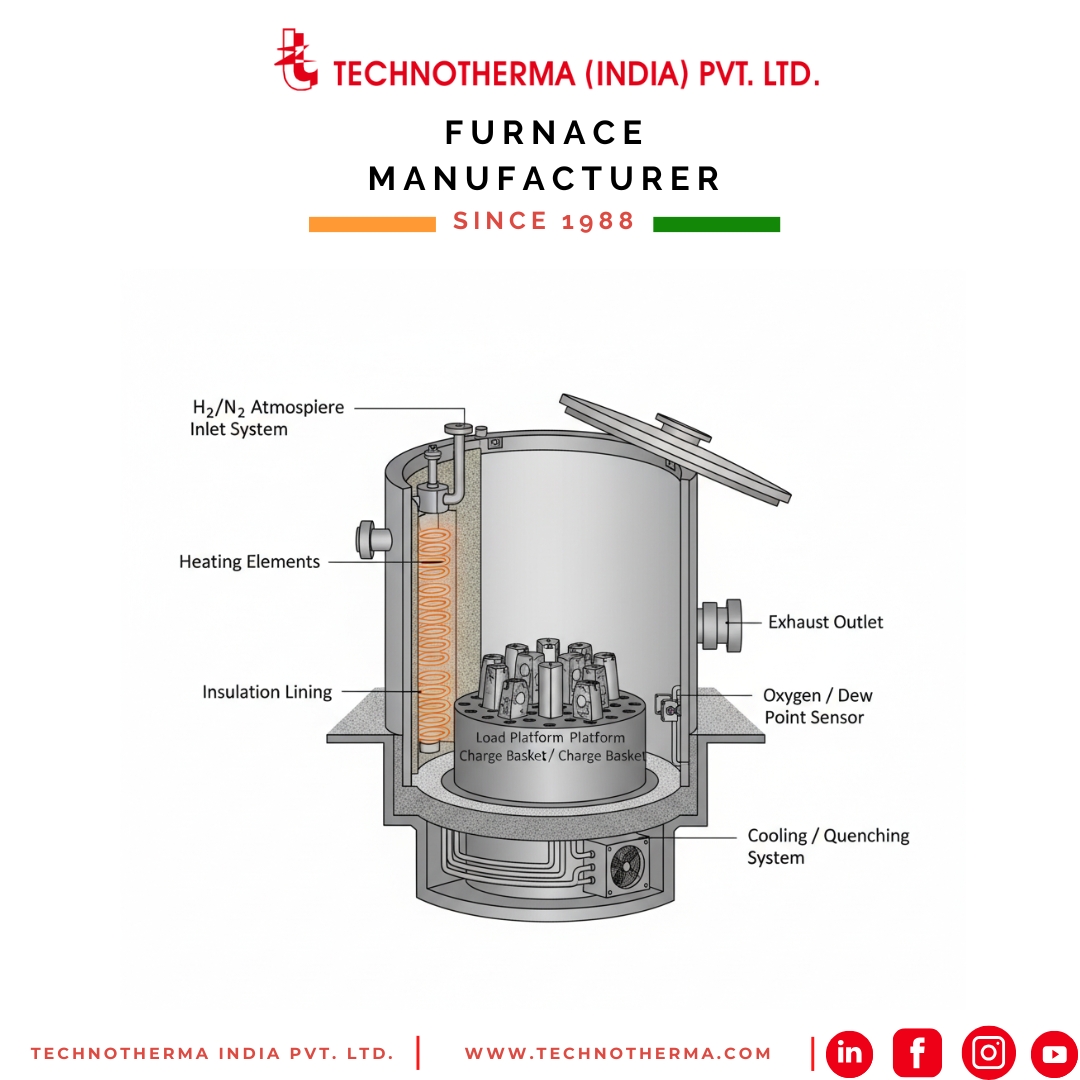

At Technotherma India Pvt. Ltd., we specialize in designing Decarb Furnaces engineered for stamping manufacturers, wire drawing plants, and specialty steel producers who demand surface precision and metallurgical consistency.

🔬 What is Decarburization and Why Does It Matter?

Decarburization is the controlled reduction of carbon content on the steel surface during heat treatment. This process eliminates unwanted surface carbides and improves ductility, machinability, and coating adhesion.

Industries such as automotive stamping, high-tensile wire production, and tool steels rely on decarburization to achieve a defect-free, scale-free finish essential for product reliability.

⚙️ Technical Specifications of Technotherma Decarb Furnaces

-

Furnace Type: Pit-Type, electrically heated with integrated H₂-rich atmosphere system

-

Heating Elements: High-resistance alloy elements with ceramic support system, designed for >20,000 operating hours

-

Power Rating (KW): Customized from 100 KW to 1200 KW depending on load capacity

-

Working Temperature Range: 600°C – 1100°C

-

Temperature Uniformity: ±5°C across working volume (as per AMS 2750 / NADCAP standards)

-

Atmosphere Control:

-

H₂/N₂ blended protective gas to prevent oxidation

-

Oxygen sensors and dew point meters for real-time atmosphere monitoring

-

-

Loading Capacity: Up to 15 MT per batch (modular design for scalability)

-

Cooling System: Forced-air / inert gas quench system integrated for faster cycle times

✅ Process Advantages

-

Stamping Industry: Reduced surface hardness → better formability and tool life

-

Wire Industry: Produces bright, scale-free wires → ready for coating, drawing, or plating

-

Precision Components: Maintains dimensional accuracy while achieving a clean metallurgical surface

-

Energy Efficiency: Optimized element design reduces kWh/ton consumption

-

Environment Friendly: Use of hydrogen minimizes carbon footprint vs. conventional oil-fired designs

📊 Performance Benchmarks

-

Cycle Time Reduction: Up to 20% faster compared to conventional designs

-

Operational Consistency: Repeatable heat-treatment profiles with PLC + SCADA-based control

-

Maintenance Interval: Extended element life and easy service access reduces downtime

-

Productivity Uptime: >95% availability ensured through robust design

🌍 Why Technotherma?

With decades of experience in industrial furnace manufacturing, Technotherma delivers custom-engineered decarb solutions that:

✔ Meet international heat-treatment standards (AMS / ISO / CQI-9)

✔ Guarantee low operating cost per ton

✔ Provide scalable configurations for future expansion

At Technotherma India Pvt. Ltd. | Furnace Manufacturer Since 1988 | we engineer not just furnaces – but process reliability and industrial excellence.