The Annealing Process: Foundation of Metal Excellence

This heat treatment:

Reduces hardness and makes the metal easier to machine and form,

-

Relieves internal stresses accumulated during previous manufacturing processes,

-

Increases ductility and toughness,

-

Ensures uniform mechanical properties, and

-

Enhances the overall quality and performance of the end product.fractory+2

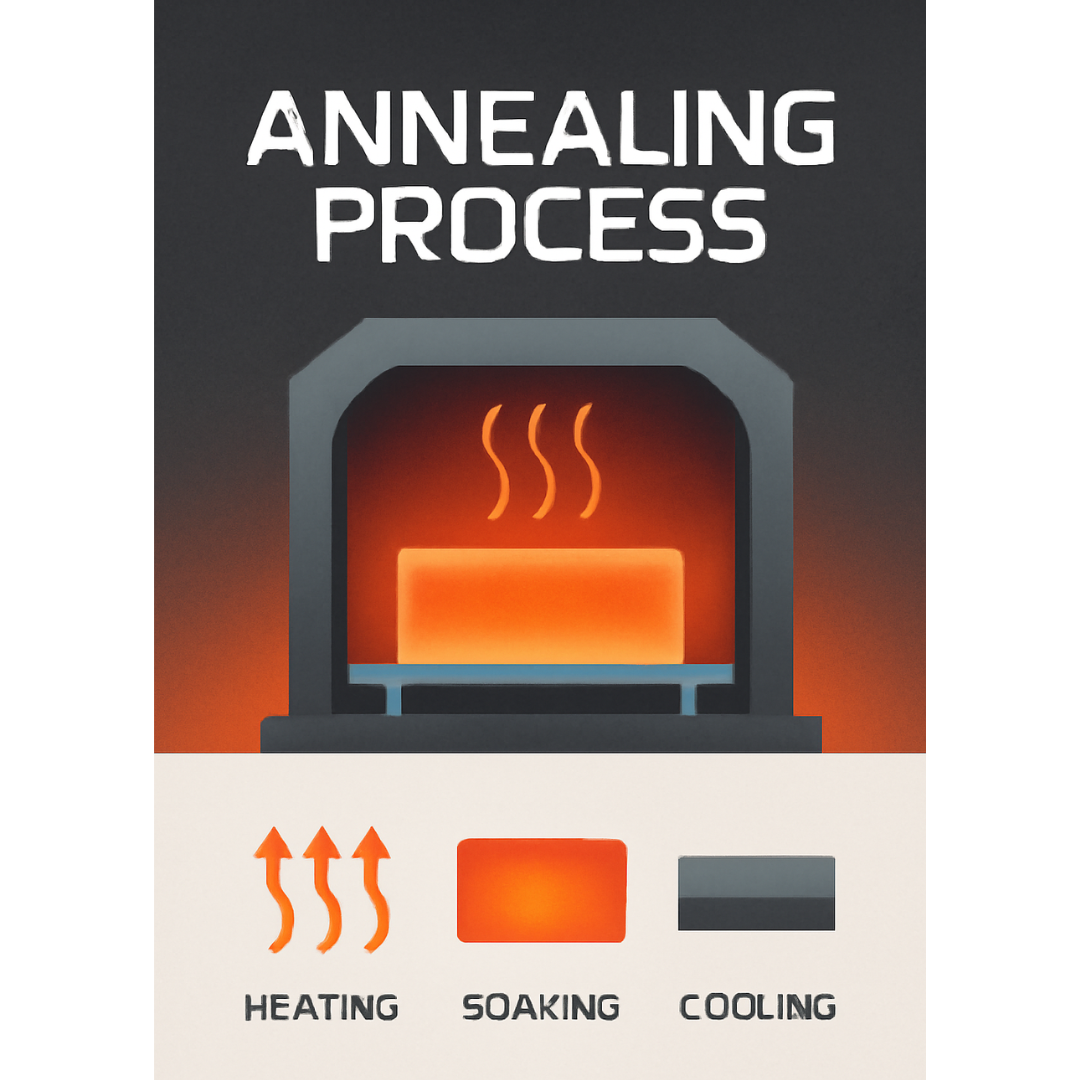

How Does Annealing Work?

The typical steps in a modern annealing cycle include:

-

Loading: Metal coils or components are loaded into the furnace, ensuring optimal spacing for uniform heat distribution.

-

Sealing: A protective cover (bell) is placed over the material to create a controlled, oxygen-free environment.

-

Heating: The furnace heats the metal to a predetermined temperature in the presence of protective gases (like nitrogen or hydrogen).

-

Soaking: The metal is held at temperature, allowing structural realignment at the atomic level.

-

Controlled Cooling: The temperature is brought down in a regulated manner to avoid distortion and ensure desired properties.

Technotherma India Pvt Ltd: Pioneering Annealing Furnace Technology

As one of the leading furnace manufacturers in India, Technotherma India Pvt Ltd has become synonymous with cutting-edge, reliable, and efficient annealing solutions for industries such as steel production, automotive, aerospace, and more. Here’s why Technotherma is considered the backbone of the industry:

1. Advanced Bell Annealing Furnace Technology

Technotherma’s Bell Annealing Furnaces are engineered for precision, energy efficiency, and automation. Unique features include:

-

State-of-the-art temperature controls for uniform heating and minimal variation.

-

IoT-enabled monitoring for predictive maintenance and real-time process analytics.

-

“Fit and Forget” Automation: The intuitive interface allows easy operation and scheduling, freeing up valuable operator time.

-

Eco-friendly operation using electric and hydrogen-based designs – making zero-carbon steel production a reality.

-

Robust safety systems for operator and equipment protection.

2. Industry-Leading Customization & Versatility

No two clients are alike. Technotherma offers:

-

Fully customizable furnace designs for specific processes and capacities,

-

Seamless integration with existing manufacturing lines,

-

Options for various heating media (electric, gas, hydrogen, oil) to suit multiple materials from steel to copper and brass.

3. Driving Green Steel Revolution

Technotherma’s electric and hydrogen bell annealing furnaces are vital for sustainable steel manufacturing. Their hydrogen atmosphere bell furnace, for example, not only prevents oxidation for superior surface quality but also supports a green manufacturing footprint.

4. Proven Track Record – The Backbone of Industry

-

Consistent product quality with reduced defects and uniform properties,

-

Reduced energy costs and optimized cycle times,

-

Minimal downtime thanks to automation and predictive maintenance,

-

Strong reputation as a key enabler for India’s rapidly expanding industrial base.

5. Full Range of Heat Treatment Solutions

Beyond annealing, Technotherma designs and manufactures a wide spectrum of furnaces for heat treatment and metalworking: black annealing, strip annealing, chamber furnaces, ammonia cracker, preheating, galvanizing, and more. This versatility ensures they serve as a one-stop partner for industrial furnace needs.

Conclusion: The Trusted Partner for Industrial Growth

If you want to elevate your product quality, drive energy efficiency, and embrace sustainable manufacturing, Technotherma India Pvt Ltd is your trusted partner. Their innovative annealing furnace technology and industry expertise are the backbone supporting India’s industrial progress, ensuring clients achieve global standards of excellence and value.