🔥 Pit Type Furnace Manufacturer – Advanced Heat Treatment for Wire & Stamping Industries

🔥 Pit Type Furnace Manufacturer – Advanced Heat Treatment for Wire & Stamping Industries

🌍 Technotherma – Leading the Future of Furnace Technology

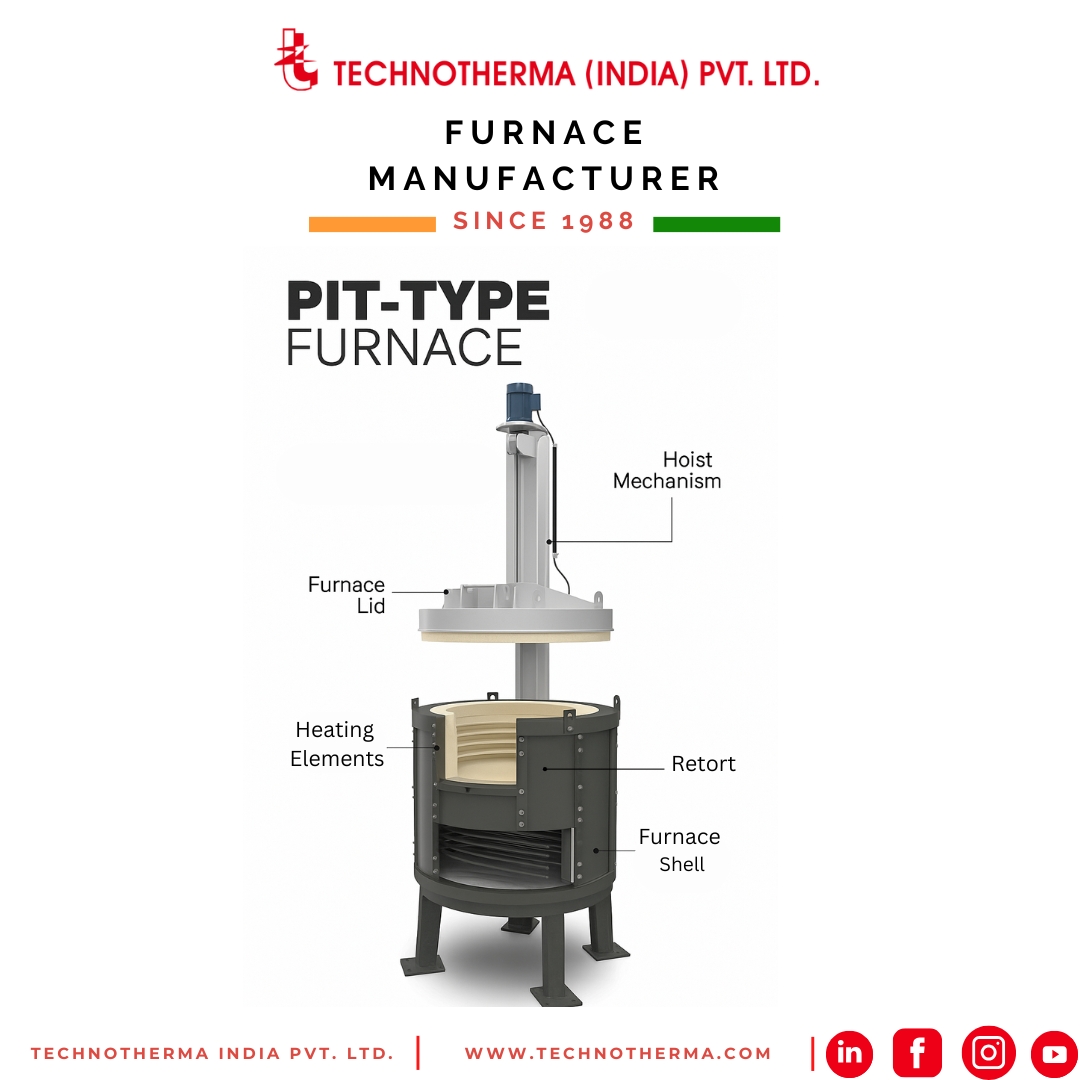

As industries evolve, the need for precision heat treatment solutions becomes more critical than ever. Among the most versatile and efficient designs is the Pit Type Furnace, trusted by wire drawing, stamping, and automotive industries for its ability to deliver uniform results, high productivity, and energy savings.

At Technotherma India Pvt. Ltd., we are proud to be recognized as a leading pit type furnace manufacturer in India, delivering solutions that combine engineering innovation with long-term reliability.

⚙ What Makes Pit Type Furnaces Special?

Pit type furnaces are vertical shaft furnaces that allow products such as wires, rods, coils, and stampings to be heat-treated with:

-

Vertical loading & unloading for easy handling

-

Efficient heat circulation around the load

-

Space-saving design with compact floor footprint

🔑 Advantages of Technotherma Pit Type Furnaces

-

Tailored for Wire & Coil Heat Treatment

-

Uniform heating ensures perfect metallurgical properties.

-

Ideal for industries where strength, ductility, and finish matter.

-

-

Energy-Efficient Design

-

High-performance insulation reduces energy loss.

-

Available in electric, gas, or oil-fired options.

-

-

Precision Temperature Control

-

Achieves ±5°C uniformity across the chamber.

-

Ensures consistent quality for every cycle.

-

-

Robust & Reliable

-

Built for continuous 24/7 operation.

-

Low maintenance, long life span.

-

🔧 Technical Highlights

-

Capacity: From 500 kg up to 20 tons

-

Temperature Range: Up to 1150°C

-

Heating Type: Gas-fired / Oil-fired / Electric

-

Controls: PLC/SCADA automation for fully programmable cycles

-

Applications: Annealing, normalizing, stress relieving of wires & stamping components

📊 Case Study: Wire Manufacturer Transformation

One of India’s leading wire producers faced challenges with inconsistent heating and high operating costs. After installing a Technotherma Electric Pit Type Furnace:

-

20% higher production throughput

-

Superior microstructure consistency

-

18% reduction in energy consumption

✅ Why Technotherma India Pvt. Ltd.?

-

Recognized as a leading furnace manufacturer in India with decades of expertise.

-

Proven track record with installations across India and overseas.

-

Customized furnace designs for specific industrial applications.

-

Dedicated after-sales support & AMC services.

📞 Conclusion

For industries requiring reliable, precise, and energy-efficient heat treatment, a Technotherma Pit Type Furnace is the solution. With our innovation-driven designs and industry expertise, we help manufacturers achieve higher productivity, lower costs, and unmatched quality.

👉 Partner with Technotherma India Pvt. Ltd. – Your trusted furnace manufacturer.