🔥 Continuous Annealing Furnace Manufacturer – Driving Efficiency in Steel Strip Processing

🔥 Continuous Annealing Furnace Manufacturer – Driving Efficiency in Steel Strip Processing

🌍 Why Continuous Annealing is the Future of Metallurgical Innovation

In modern steel strip production, annealing plays a pivotal role in tailoring mechanical properties such as ductility, tensile strength, and hardness. Traditional batch furnaces, while effective for small-scale operations, fall short in meeting the demands of high-speed, precision-driven industries.

Enter the Continuous Annealing Line (CAL)—a fully integrated solution engineered for automotive-grade steel, galvanized sheets, and high-strength low-alloy (HSLA) steels. At Technotherma India Pvt. Ltd., we specialize in designing and commissioning continuous annealing furnaces that deliver uniformity, scalability, and energy efficiency.

⚙️ What is a Continuous Annealing Furnace?

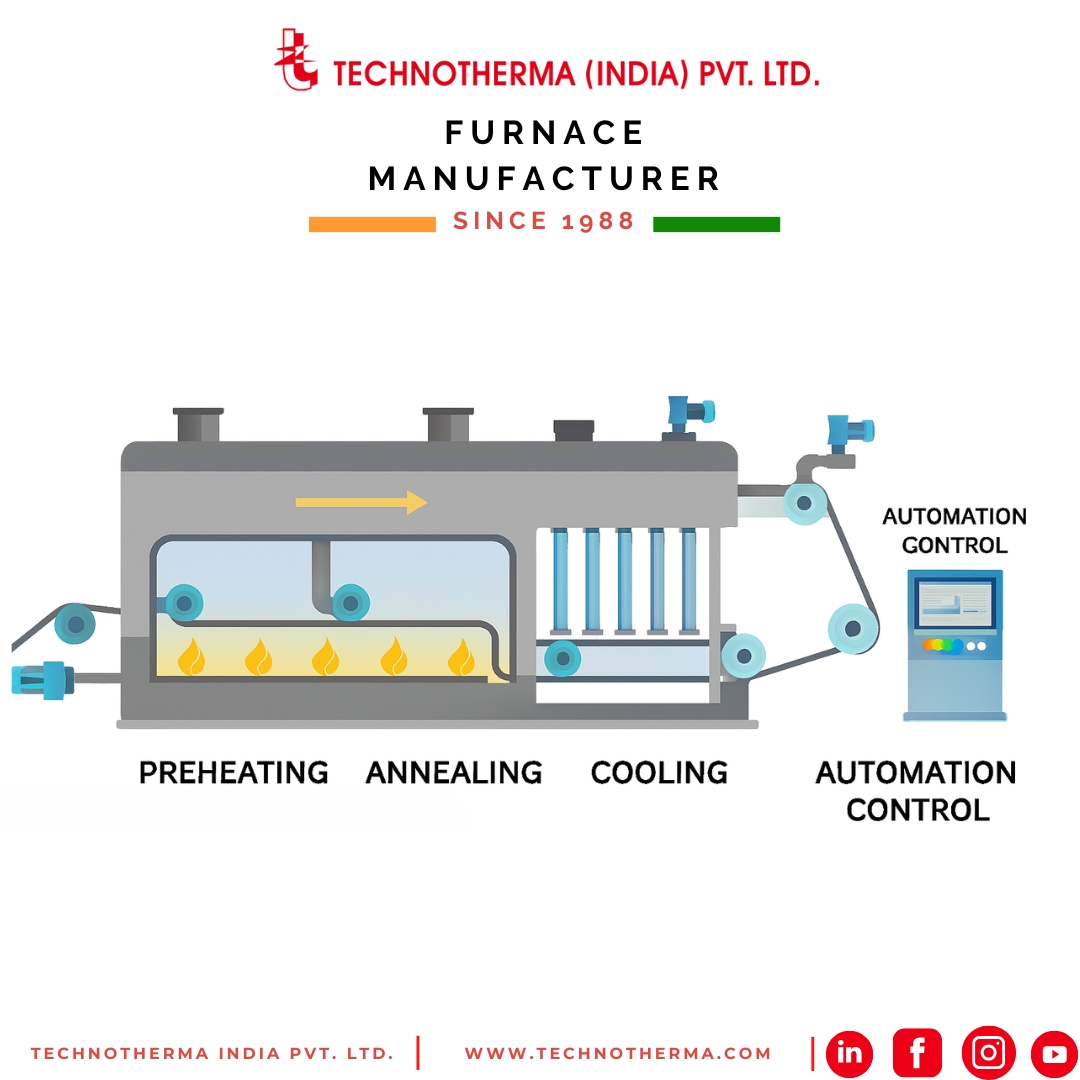

A Continuous Annealing Furnace (CAF) is a multi-zone thermal processing system where cold-rolled steel strips are continuously fed through:

- 🔸 Preheating Zone – Rapid temperature ramp-up using gas-fired or electric heating

- 🔸 Soaking/Annealing Zone – Controlled dwell time for recrystallization and grain refinement

- 🔸 Cooling Zone – Forced or controlled cooling to achieve desired microstructure

This uninterrupted flow ensures consistent metallurgical properties across the entire coil length, critical for downstream forming and welding operations.

🔍 Key Engineering Advantages of Technotherma CAL Systems

📈 High Throughput & Line Speed

- Designed for 24/7 operation with minimal downtime

- Line speeds up to 200 m/min, depending on strip grade and thickness

🧪 Metallurgical Precision

- Uniform grain size distribution and phase transformation control

- Ideal for dual-phase steels, TRIP steels, and IF steels

⚡ Energy Optimization

- Low-NOx burners, regenerative heating, and hybrid electric options

- Advanced insulation materials reduce thermal losses

🛠 Automation & Control

- PLC/SCADA-based control systems with recipe management

- Real-time monitoring of strip tension, temperature, and atmosphere composition

🔄 Process Versatility

- Handles strip thickness from 0.2 mm to 3.0 mm

- Compatible with hot-dip galvanizing, pickling, and skin-pass mill integration

📐 Technical Specifications

| Parameter | Specification |

| Strip Thickness | 0.2 mm – 3.0 mm |

| Strip Width | Up to 1500 mm |

| Furnace Temperature | 600°C – 850°C |

| Heating Source | Gas-fired / Electric / Hybrid |

| Atmosphere Control | Nitrogen, Hydrogen, or Mixed Gas |

| Automation | PLC/SCADA with HMI & remote diagnostics |

| Applications | Automotive steel, galvanised sheets, HSLA steels |

📊 Real-World Impact: Automotive Steel Case Study

A Tier-1 automotive steel producer partnered with Technotherma to install a custom-engineered CAL system. Results within 6 months:

- ✅ 40% increase in coil output

- ✅ 25% reduction in rejection rates

- ✅ Improved tensile strength consistency across batches

- ✅ Enhanced weldability and formability for automotive components

🏆 Why Technotherma India Pvt. Ltd.?

- 🔧 Decades of expertise in industrial furnace design, commissioning, and automation

- 🌐 Recognized as a top continuous annealing furnace manufacturer in India

- 🤝 Proven track record with steel mills, automotive OEMs, and strip processors

- 🔄 End-to-end support: Design → Manufacturing → Installation → After-sales

📞 Ready to Transform Your Strip Processing Line?

If your operation demands precision annealing, energy savings, and scalable production, Technotherma’s Continuous Annealing Furnaces are the solution.

👉 Contact Technotherma India Pvt. Ltd. | Furnace Manufacturer since 1988 – Your Engineering the future of steel strip processing.