Technotherma’s Electric Galvanizing Furnace – Engineered for Higher Productivity & Longer Pot Life

Technotherma’s Electric Galvanizing Furnace — Engineered for Higher Productivity & Longer Pot Life

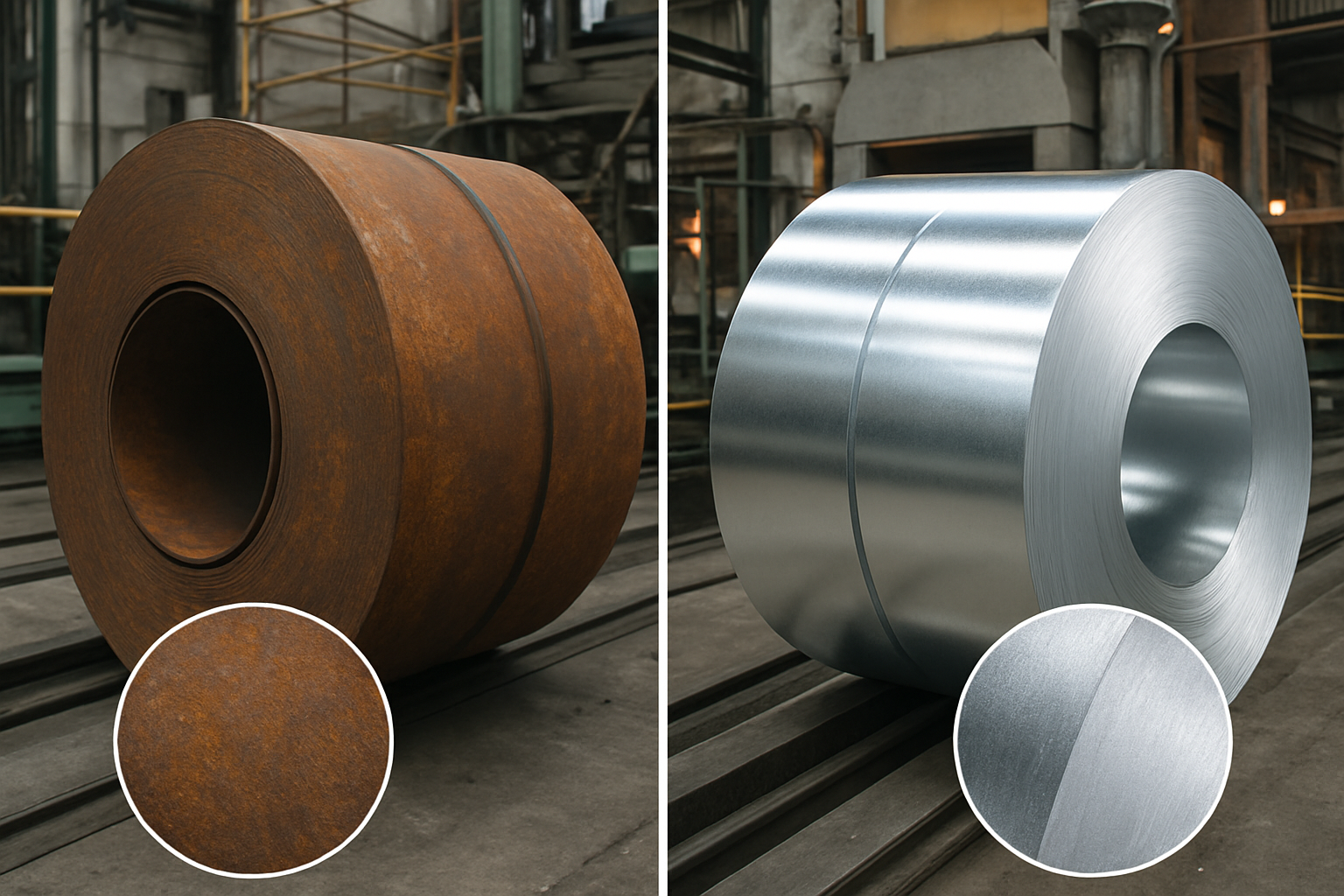

The rising demand for corrosion-resistant steel across industries such as construction, automotive, railways, power transmission, and infrastructure is driving a rapid expansion in galvanizing operations. At the heart of this process is the galvanizing furnace—an essential piece of equipment that determines production efficiency, zinc pot life, and overall operational cost-effectiveness.

At Technotherma India Pvt. Ltd., we specialize in precision-engineered electric galvanizing furnaces designed to deliver uniform heating, high energy efficiency, and exceptional durability.

How Does a Galvanizing Furnace Work?

A galvanizing furnace is engineered to melt and maintain zinc at the optimal working temperature (approximately 440°C – 460°C). The process involves several critical steps:

-

Charging & Heating: Zinc ingots are loaded into the furnace pot and melted by controlled heating.

-

Temperature Control: Electric heating elements or radiant tubes provide even heat distribution, avoiding hot spots and localized overheating.

-

Dipping & Coating: Cleaned steel products such as wires, sheets, or components are immersed into the molten zinc bath to achieve corrosion-resistant coating.

-

Cooling & Withdrawal: Coated products are extracted and cooled, creating a metallurgically bonded zinc layer for long-lasting protection.

Technical Requirements of a Modern Galvanizing Furnace

To meet industry demands, a galvanizing furnace must ensure:

-

Precise temperature uniformity (±5°C) for consistent coating quality.

-

Optimized loading design tailored to various product forms (wires, tubes, sheets).

-

Efficient electric heating systems coupled with advanced insulation to minimize heat loss.

-

Robust refractory design that withstands zinc corrosion and repeated thermal cycling.

-

Extended pot life through innovative design to reduce hot spots and maintenance frequency.

Electric vs Gas-Fired Galvanizing Furnaces: A Technical Comparison

| Parameter | Gas-Fired Furnace | Electric Furnace (Technotherma) |

|---|---|---|

| Heating Medium | Burners (direct/indirect heating) | High-performance electric heating elements |

| Temperature Control | ±15°C (less precise) | ±5°C with multi-zone PID control |

| Energy Efficiency | ~55–60% (heat loss through exhaust) | ~80–85% (minimal heat loss) |

| Maintenance | High (burners, valves, piping) | Very low (no burners, fewer moving parts) |

| Pot Life | 3–4 years (localized hot spots) | 6–8 years (uniform heating, extended pot life) |

| Environmental Impact | Produces combustion gases, needs ventilation | Zero combustion gases, eco-friendly |

| Automation | Limited | Easily integrated with PLC/SCADA for digital monitoring |

| Operating Cost | Lower fuel cost; higher maintenance | Slightly higher electricity cost; overall lower lifecycle cost |

Technotherma’s Engineering Excellence

Our electric galvanizing furnaces incorporate advanced engineering features to optimize performance and longevity:

-

Customized kW rating tailored for specific load and throughput requirements, ensuring rapid melting and stable temperature.

-

State-of-the-art multi-zone temperature control with PID logic for precise bath temperature management.

-

Durable special heating elements resistant to zinc vapor corrosion for extended service life.

-

Pot life extension beyond 6 years by minimizing hot spots and thermal stress.

-

Multi-layer insulation systems for low heat loss and energy savings.

Proven Benefits for Our Customers

Clients utilizing Technotherma’s Electric Galvanizing Furnaces report:

-

20–25% increase in production output due to stable bath temperature and consistent melting.

-

Significant reduction in maintenance downtime from design improvements and lower component wear.

-

Stable zinc coating quality through tight temperature control and uniform heat distribution.

-

Lower operating costs achieved through higher energy efficiency and less frequent pot replacements.

-

Extended zinc pot and refractory life, lowering replacement frequency and downtime.

Why Choose Technotherma India Pvt. Ltd.?

With decades of expertise in industrial thermal processing, Technotherma is the partner of choice for industries demanding durable, efficient, and innovative furnace solutions.

Our galvanizing furnaces are:

-

Custom-built to match specific galvanizing application needs.

-

Future-ready with automation and advanced digital controls for easy integration into modern production lines.

-

Supported with strong after-sales service and technical guidance to ensure smooth operations.

Conclusion

Galvanizing is more than just steel protection; it is about ensuring long-term reliability and reducing lifecycle costs. Technotherma India Pvt. Ltd.’s Electric Galvanizing Furnace empowers industries to achieve:

✔ Higher productivity

✔ Longer pot life

✔ Lower maintenance

✔ Superior coating consistency

Contact us today to explore solutions tailored for your galvanizing needs and discover how our technology can transform your operations.